INFINITY DRY-RUNNING PISTON COMPRESSORS WITH ELECTRO-HYDROSTATIC DRIVE

For many decades, sera has been providing reliable solutions for the oil-free, contamination-free, and leak-free compression of gases. The newly developed innovative dry-running piston compressors with electro-hydrostatic drive complement the proven metal diaphragm technology perfectly. With them, lubricant-free, particle-free gases such as hydrogen, nitrogen, helium, argon, or ethylene can be reliably and energy-efficiently compressed to high pressures. These innovative piston compressors from sera are particularly suitable when large quantities of gas need to be compressed economically and safely.

Due to the vertical design and the concept of the compressor units, contamination of the medium by hydraulic oil from the drive system is excluded. Complex and expensive sensors for detecting the drive fluid can be safely omitted.

ADVANTAGES AT A GLANCE

• Oil-free and secure compression

• Robust design

• High availability

• Energy-efficient drive

• Compact footprint

• Service-friendly

APPLICATION AREAS

• Hydrogen refueling stations

• Power-to-Gas

• Technical gases

• Airbag inflators

• Hot isostatic pressing

• Pressure testing technology

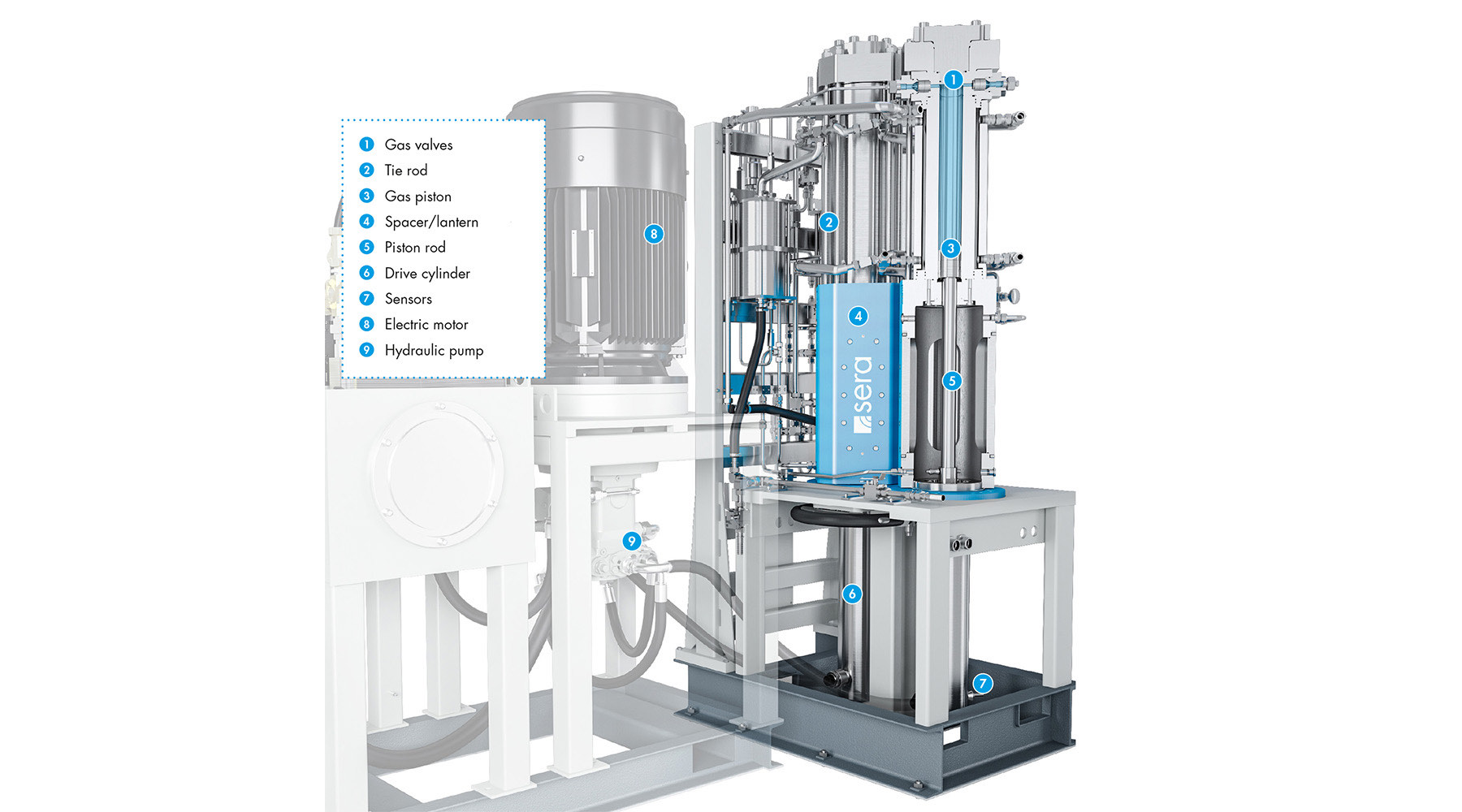

The compressor unit consists of two coaxially arranged, vertically standing gas cylinders, each mechanically connected to a hydraulic cylinder and driven by them. There is a space between the gas cylinder and the drive cylinder, ensuring that hydraulic oil does not contaminate the medium. The two drive cylinders are hydraulically connected to each other through a connecting line.

The gas cylinders are liquid-cooled by a cooling jacket, which dissipates frictional heat and significantly extends the lifespan of sealing and guiding systems.

The hydraulic cylinders are driven by a hydraulic unit. When using a system with a control pump, the change in piston stroke can be continuously regulated. The control of the stroke direction change is achieved through non-contact proximity switches.

The use of a swiveling axial piston pump is particularly advantageous, as it allows the direction change of the drive cylinders to be realized directly by the pump itself. This creates a high-energy efficiency electro-hydrostatic drive system. By eliminating loss-prone directional control valves, the drive cylinders are directly pressurized by the oil flow from the hydraulic pump, resulting in a robust drive system with integrated overload protection.

For more information about our innovative piston compressor with electro-hydrostatic drive, please refer to the download section.

DOWNLOAD

LinkedIn

LinkedIn Instagram

Instagram